High frequency plate splicer (push-type)

Release Time:2021-08-30

· High-frequency splicing machine, also known as high-frequency splicing machine, is a commonly used material processing equipment in the wood industry. Splicing equipment splices smaller volumes of wood (veneer, bamboo board) into larger volumes of materials. Compared with cold jointing and other heating methods, the equipment has the advantages of high automation, wide range of adaptation and low cost of jointing.

· Application range High frequency splicing machine is suitable for finger splicing board, integrated wood splicing board, solid wood edge sealing, L-shaped door line and so on.

· Equipment characteristics

· 1. Fast splicing speed.

· 2. High degree of automation.

· 3. Wide range of adaptation.

· 4, low gluing cost.

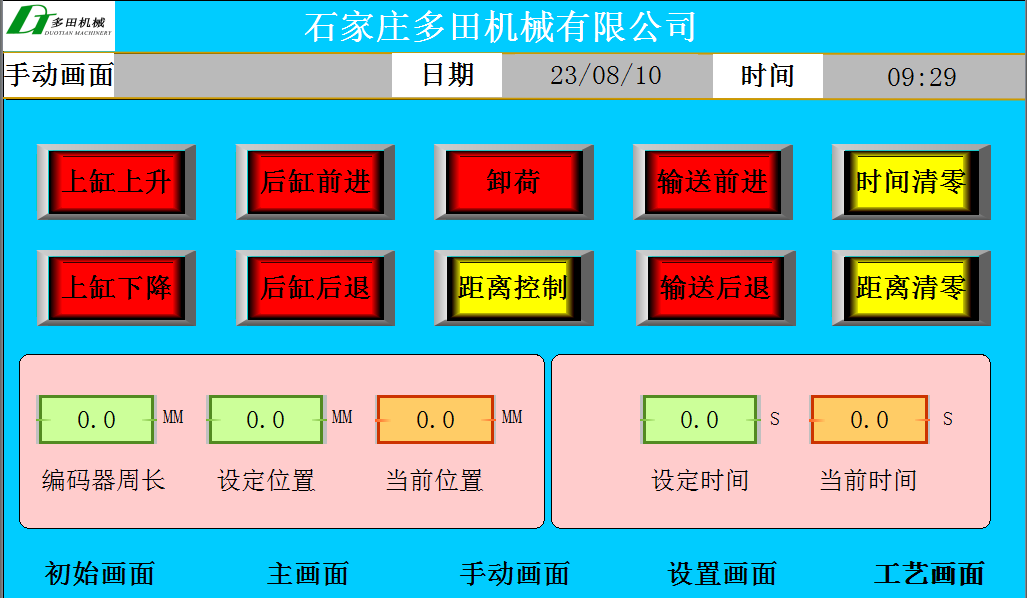

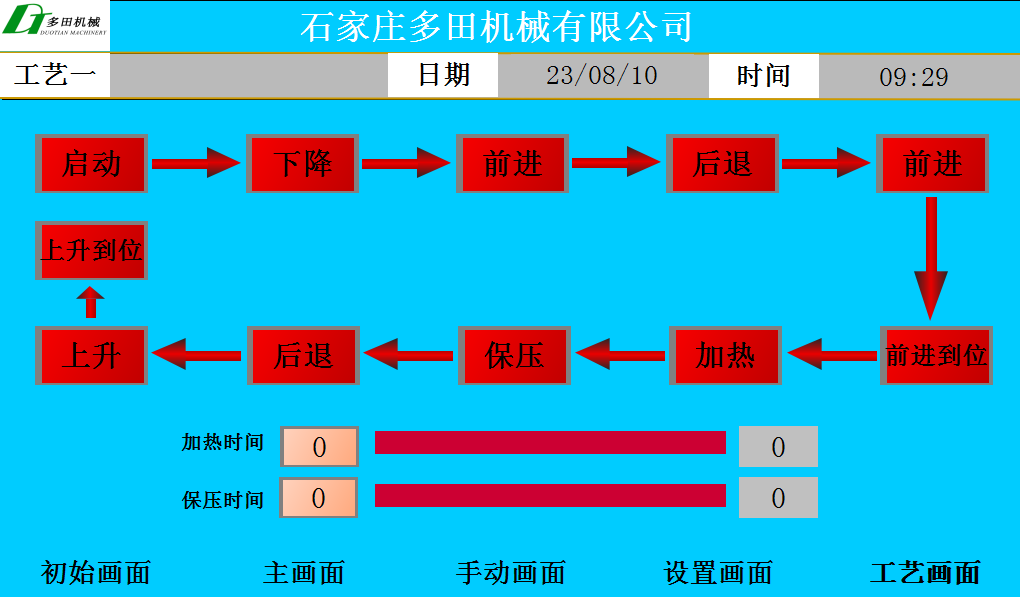

· 5, humanized operation, PLC and touch screen program control.

· Intelligent operating system

Parameter

| Model | GPB-2513-DT-50L | GPB-3213-DT-60L | GPB-4213-DT-80L | GPB-6213-DT-120L |

| Minimum Gluing size (mm) |

2500*1300 | 3200*1300 | 4200*1300 | 6200*1300 |

| Total pressure (T) | 50/60/85/120 | |||

| Control mode | PLC touch screen program automatic control | |||

| Frequency (MHZ) | 6.78 | |||

| Maximum Gluing Thickness (mm) |

≦60 | |||

| HF output power (KW) | 20 | 20 | 30 | 50 |

| ***** can be customized according to different needs of customers. * * * * | ||||

haode5858@126.com

haode5858@126.com 0311-83506165

0311-83506165

冀公网安备 13012302000304 号

冀公网安备 13012302000304 号